Conveyor Ovens

Conveyor Ovens Repair and Maintenance

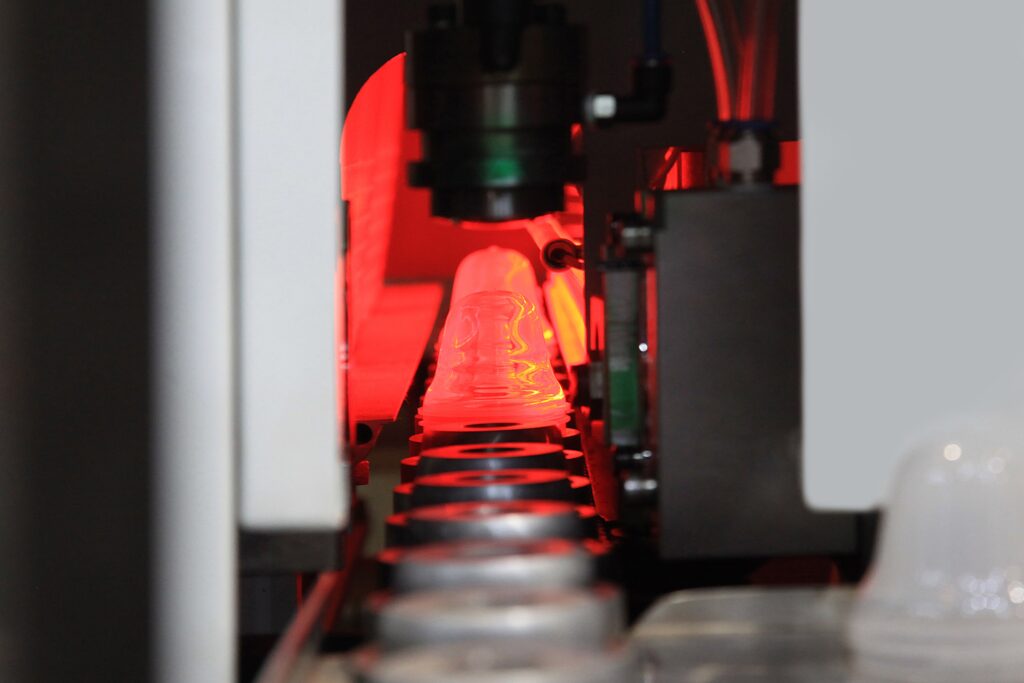

Conveyor ovens are one of the most versatile pieces of equipment in any commercial kitchen, and they come in various sizes and styles to suit any need. Whether you’re looking to speed up your cooking process or ensure that your food is cooked evenly, a conveyor oven comes in handy. However, like any other kitchen equipment, conveyor ovens require occasional repair and maintenance to keep them running smoothly.

So, how can your oven get to be so messed up? The simplest answer is that it’s not just one factor but several issues all coming together to form a big problem. The usual culprits are a lack of regular cleaning, food or grease build-up, and overuse. These can lead to problems with the conveyor belt, the heating element, or the motor.

Maintenance Tips To Keep your Conveyor Oven In Shape

- Clean your oven regularly. At least once a week, you should disassemble the conveyor belt and give it a good scrub down. The same goes for the oven chamber – give it a good wipe-down with soapy water and a sponge

- Lubricate moving parts regularly. Have a schedule for lubrication (monthly, bi-weekly, etc.) and stick to it. Be keen on unnatural noises and vibrations coming from the oven. A quick and simple lubrication job might just be what it needs

- Ensure that the pulley alignment is correct. The conveyor belt runs over several pulleys; if they’re not aligned properly, it can cause the belt to come off track or even break

- Check the bearings on your conveyor rollers. If they are starting to show signs of wear, have us replace them before they break down completely and cause bigger problems

- Ensure the door seals on your oven are tight and in good condition. Look for any cracks, fraying, or other damage. If you see any damage, replace

- Remove any food or grease build-up as soon as possible

Reasons To Schedule Regular Maintenance

Like any other piece of machinery, conveyor ovens will run more efficiently if they are well-maintained. Regular maintenance is essential to keeping your conveyor oven running at peak performance. Here’s why:

1. Just like changing the oil in your car, regular maintenance on your conveyor oven can help to extend its life. By keeping the moving parts well-lubricated and ensuring that the electrical components are in good working order, you can add years of life to your oven

2. By identifying minor problems before they become big ones, you can avoid the need for costly repairs down the line

3. Improve the quality of your food and ensure food safety

4. Reduce the risk of a production line stoppage

5. Ensure food safety

Average 5-star reviews

Based on 75+ user reviews

Frequently Asked Questions.

You’ll find answers to common questions about our HVAC services. Our aim is to help you understand more about how we can assist with your heating, cooling, and air quality needs.

We recommend having your conveyor oven serviced at least once a year or more often if it is in heavy use. Additionally, it’s a good idea to have the oven inspected any time you make a change to your production line, as this can affect how the oven operates.

During a service call, our technicians will clean the oven, inspect the moving parts, and test the electrical components. If any repairs are needed, we will make them at that time and advise you of any parts that may need to be replaced in the future. We will also lubricate the moving parts and make any necessary adjustments.

The cost of a service call will vary depending on the size and type of oven and the extent of the work that needs to be done. However, we offer competitive rates and will work with you to keep the cost of service as low as possible.